Type D Jumbo Bags (Dissipative)

FIBCs/Bulk Bags

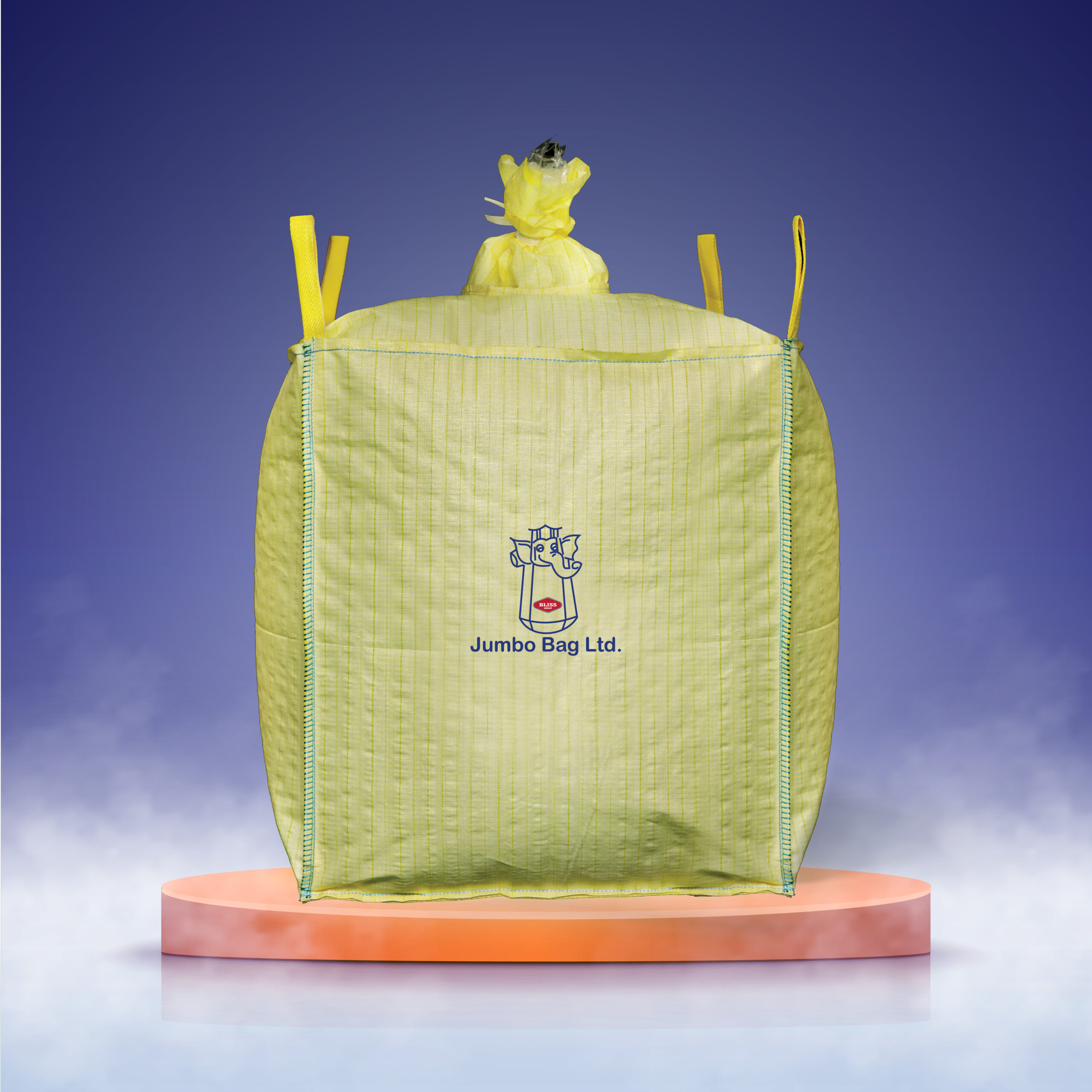

Introducing the Most Prestigious Product of Jumbo Bag Ltd – Type D Bags!

Jumbo Bag Ltd is a global leader in producing all types of static Protective Jumbo bags / FIBCs based on standard IEC 61340, including the prestigious Type D bags. We design these bags while considering the minimum ignition energy (MIE) value and filling atmosphere to ensure 100% protection against static hazards during filling and discharge operations.

Our Type D bags come with or without lamination and with or without liners, making them a versatile solution for various applications. The filling and emptying of flexible intermediate bulk containers (FIBCs) can generate high levels of static charge, which can be dangerous. However, With our Type D Jumbo bags, you can rest assured that your operations are always safe. We provide a diverse selection of Type D bags that are manufactured in various sizes and capacity ranging from 250 kgs to 2500 kgs

What sets us apart from others is that we produce Type D FIBCs in-house, from raw material to final bag. We follow a rigorous testing protocol at every stage of production, including tape, fabric, lamination, and liner bags, to ensure the bag’s safety against static hazards. Our state-of-the-art world-class lab conducts various tests, such as surface resistivity, breakdown voltage, charge decay, corona charge, and resistivity to ground in a controlled atmosphere.

Our commitment to quality and safety is further demonstrated by the fact that our Type D bags are also tested by Dekra (Chilworth ,USA) according to standard IEC-61340 to confirm Type D requirements.

Trust Jumbo Bag Ltd for all your Type D FIBC needs and experience the peace of mind that comes with knowing you are using the safest and most reliable bags in the market.

Our Customized Type D

| Fabric | Made of Polypropylene UV Stabilized in Various GSM & Coloured fabrics |

| Design | U panel, Circular, 4 Panel, Baffle and Baffle Lined, UN designs |

| UV Stabilization | All components of the FIBCs are UV stabilized |

| Safe Working Load | Up To 2500 kgs (5500lbs) |

| Safety Factor | Up To 8:1 |

| Filling Spout | Customized |

| Discharge Spout | Customized |

| Liner | Static protective Liner, Formfit Liner, Glued Liner, Sewn Liner. With & without Tabbing arrangement. |

| Printing | Upto 4 colors and upto 4 sides. |

| Traceability | UNIQUE ID is provided for each and every bag to track back from resin stage to finished Bag stage. |

| Sift Proof | Single, Double & Triple side Sift Proof are provided. |

| Test Certificate | In-house test certificate will be provided for all the shipments. Our Jumbo Bags get tested with International test House also. |

Why our Jumbo stat (Dissipative) Jumbo Bags

(Type D)

| Technology | Permanent Antistatic |

| Manufacturing Capability | In-house Production |

| Process Control | Since the bags are produced in-house, ensuring process control right from yarn/tape, Fabric, Lamination and finishing the bag. |

| Testing Lab | Fully equipped test lab to monitor complete in process and final product |

| Testing done | Breakdown Voltage, Charge Decay, Corona charge |

| ColourCustomization | Standard colour White & Yellow, customization possible |

| International test report | Tested multiple times to ensure the FIBC performance (Discharge Incendivity test) in Chilworth (Dekra )Lab - USA |