Liner Bags

FIBCs/Bulk Bags

Jumbo Bag Ltd, also offers a variety of liners, including with and without tabbing, to protect the contents from moisture, light, or other environmental factors. Our facility includes Mono and a 3-layer co-extruder plant to create multi-layer bags that have improved strength, durability, and barrier properties.

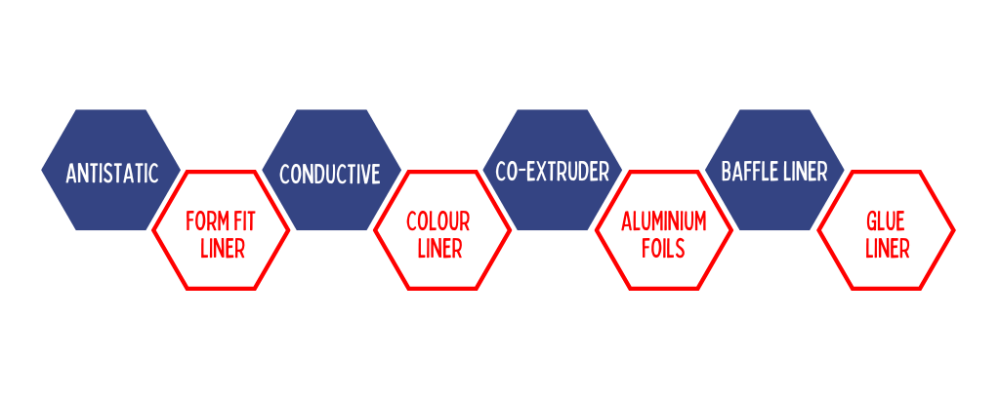

Types of Liners

Conductive co-extruder liners

These liners are made by using a 3-layer co-extruder plant that combines a conductive layer with other layers of plastic material.

HD (High-Density) Liners

These liners are made from high-density polyethylene (HDPE), which is a strong and durable plastic that provides excellent barrier properties and puncture resistance.

PP (polypropylene) liners

These liners are made from polypropylene, which is a thermoplastic polymer that is known for its strength, durability.

Barrier Liners

These are utilized to shield products from moisture and enhance several physical characteristics, ultimately preserving the product's freshness by achieving optimal oxygen transmission rates (OTR) and water vapor transmission rates (WVTR).

Aluminium Foil Liners

Aluminium foil liners provide an additional layer of protection by blocking light, air, and moisture to help maintain product freshness and extend shelf life.

L2 Liners

L2 liners are used for Type B,

Type C and Type D bags to give utmost static protection during filling and discharge operation.